J.E. Holtzinger Engineering Building

Automation Lab - Room 203

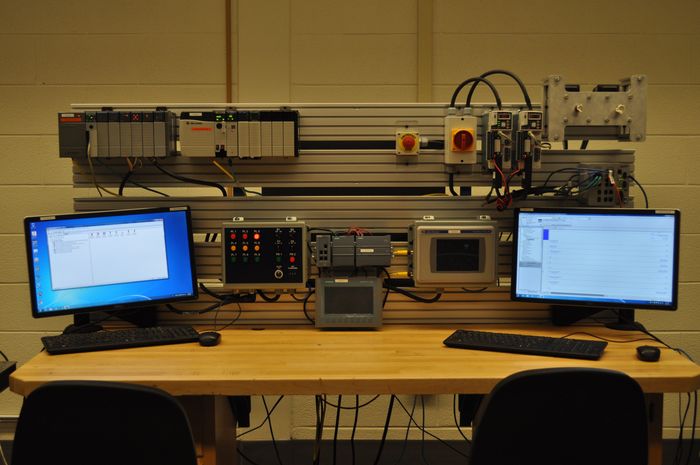

In the Automation Lab, there are eight benches where sixteen students work with Programmable Logic Controllers (PLCs), robots, motion controls, and a sorting and assembly process composed of various industrial sensors and actuators.

Programmable Logic Controllers - Students learn to program PLCs (Programmable Logic Controllers), which are used in industry to control processes. Located at each PLC bench are three PLCs, an Allen Bradley SLC 5/05, an Allen Bradley ControlLogix processor, and a Siemens Simatic S7-1200 CPU . Students program the PLCs using simple inputs and outputs (switches, pushbuttons, and lights) in the introductory course. In the subsequent course, students accomplish a sorting, assembly and inspection process by utilizing a variety of sensors and actuators used in combination with PLCs and programming. Throughout the PLC sequence, students learn to program using in a variety of languages.

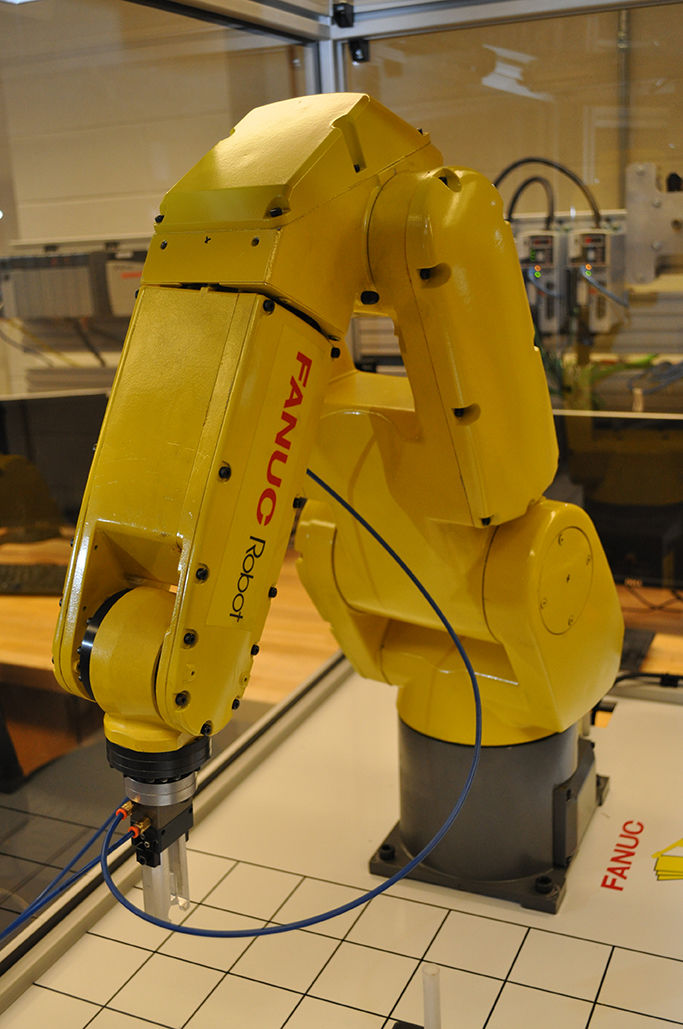

Robots - The FANUC anthropomorphic robots have five axes which control movement, as well as grippers which open and close, allowing them to pick up and put down parts.

Materials Testing Lab/Mechanical Lab - Room 204

- Instron Tensile Testing Machine

- Impact Tester

- Hardness Tester

- Heat Treatment Ovens

The Materials Testing Lab provides access to an Instron tensile tester, heat treatment ovens, a Charpy impact tester, and assorted hardness testers.

Students perform material testing on specimens and analysis of data. Tensile testing is accomplished with an Instron machine to evaluate material strength. Students utilize an Equotip hardness tester to determine the resistance to permanent deformation under dynamic loading. Impact strength is assessed using a Tinius Olsen Charpy impact tester.

Ralph and Helen Force Advanced Technology Center

Project Lab 1 - 103 Force

Senior-level students utilize this lab to complete the assembly of their senior design projects each semester. The lab is equipped with a large variety of tools and components to aid in the completion of the Senior Capstone Design Project.

Manufacturing Lab – 104 Force

CNC Machining equipment - Students learn the proper procedures for programming Computer Numerically Controlled (CNC) equipment in order to machine parts. Both a CNC mill and CNC lathe are used.

Laser Engraver - Students cut precision parts for use in assembling models using either a 50 Watt EPILOG Legend EXT laser engraver, or a 75 Watt EPILOG Legend EXT laser engraver.

Projects Lab II – 106 Force

This second Projects Lab is also used for assembly of projects in the EMET capstone design course (EMET 440) and houses the college's Motorsports Club BAJA SAE vehicle. This lab is outfitted with an overhead hoist, a floor lift, overhead air lines and electrical lines, hand tools, and assorted power tools.

Machine Shop - 107 Force

The Machine shop is equipped with two manual mills, a manual lathe, a HAAS conversational CNC lathe, an iron worker, a sheet metal worker, a horizontal and a vertical band saw, plasma cutter, and several different types of welding equipment, MIG, TIG, and stick to name a few. Students receive instruction in general laboratory safety and specific instruction in the use of each of the machines. They can then make use of this equipment in class projects as well as in their senior design project work.

Process Control Lab - 207 Force

Students learn about process controls in junior and senior level coursework. They use various process control workstations, computer-controlled data acquisition equipment, and control system development and simulation software.

Electrical Labs – 207, 208, and 209 Force

Three general electrical engineering laboratories accommodate hands-on study of electric circuits and advanced electronics. The facilities are equipped with customary laboratory instruments such as oscilloscopes, power supplies, function generators, and multi-meters. Integrated PC-based workstations are also available for design, testing, measurement, and analysis of electrical and electronic circuits. Computer-assisted circuit design simulation, and rapid prototyping are supported by a variety of software packages including Matlab/Simulink, DSpace, LabView, Code Composer Studio, Xilinx, and MultiSim.

Additional Electrical Equipment: Experiments in AC and DC rotating electric machinery and electric drives are supported by configurable motor/dynamometer workstations. Supporting equipment for these experiments includes high voltage power supplies, AC and DC motors and generators, dynamometers, optical encoders, programmable power electronics boards, and electrical load banks. PC-based workstations and the programmable power electronics modules are used to support experiments with variable speed AC and DC motor drives. Digital electronics and microprocessor laboratories are equipped with modern FPGA (Field-Programmable Gate Array) boards, ARM Cortex Processor boards, and various microprocessor, microcontroller, and DSP (Digital Signal Processor) development boards.

Hawthorn Building

Project Lab (EDSGN 100 project lab) - 256 Hawthorn

Advanced Computer Lab w/ AMX push-button controls - 257 Hawthorn

General Purpose Computer Lab/Classroom - 259 Hawthorn

Eiche Library

Computer Lab – 140 Eiche

A designated open computer lab is available for students in the EMET program. This lab offers all of the software packages used throughout the program. Students are able to freely access this computer lab to work on course material outside of the classroom that may require specific software.

Computer Lab – 154 and 155 Eiche

A state-of-the-art computer labs is used for instruction in the EMET program. The 64 seat computer lab has a retractable wall to allow for two separate classrooms, or one large group room.

The CAMP – 125A Eiche (WPS Office Solutions 3-D Printer Lab)

The Center for Additive Manufacturing and Printing (CAMP) was created to provide a resource for students, faculty, and staff across the Penn State Altoona campus community. All members of this community are afforded the opportunity to explore Additive Manufacturing (3D printing) and to begin to understand how this disruptive technology will change the future. The CAMP is currently equipped with Stratasys Fortus 250mc, Stratasys Dimension SST, and 3D Systems Projet 460 Plus 3-D printers; NextEngine 3D scanner; HP 42” large format printer/plotter; EPSON archival quality printer; Roland vinyl cutter. For more information, visit The CAMP website.